Point ownership

Point ownership![[MAT logo]](../../../images/MAT-linux-h100.gif)

Points may be 1-bit, corresponding to discrete inputs, outputs, internal/memory coils, flags etc, or multi-bit (up to 32-bit), corresponding to analog inputs, outputs, integer or floating point registers etc.

Points are defined in the PLC section of the config.

Point ownership

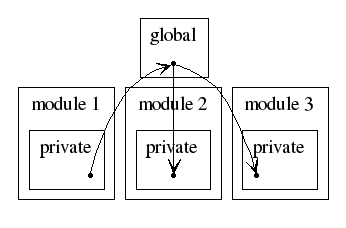

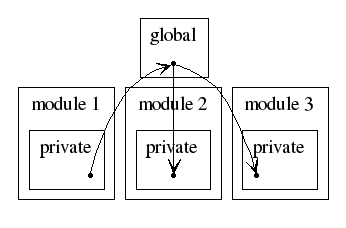

Point ownershipThe diagram on the right shows the situation for one point and three modules: the point is owned by module 1. It has a private copy of the point, and is allowed to write to it. At the bottom of the scan, the point is copied to the global area, from which it is copied to modules 2 and 3 at the top of their scans.

This means that while troubleshooting, if the point has an incorrect value, we know to check module 1.

For instance, in the basic demo, there are the following points:

L1, L2, L3, L4

left, right quit The declaration in the config file looks like this:

point L1 "light 1" Chaser point L2 "light 2" Chaser point L3 "light 3" Chaser point L4 "light 4" Chaser point left "<- (key L)" Kbd point right "-> (key R)" Kbd point quit "quit (key Q)" Kbd

All of the points are also displayed on the screen, by the vitrine module. No special access configuration needs to be done to allow this - any module may read any point it wishes; it's only changing them that's restricted.

In the modbus demo, the

L1, L2, L3 and L4

points are also sent to the Modbus slave.

A: In the MatPLC, all modules are written by one module (the "owner") and read by all modules. There is no way to have a point that could be written by two modules which are both active at the same time.

It's probably better to have a separate point for each module that wants to write, anyway, and then have explicit logic deciding between those values. That way if the wrong value comes out, you know where to look for the problem...

For instance, you might have:

foo_auto

foo_manual

if automatic_mode

then copy foo_auto to foo_cur

else copy foo_manual to foo_cur

foo_cur

$Date: 2006/03/06 04:20:16 $